Tilmaamaha Badeecada

-

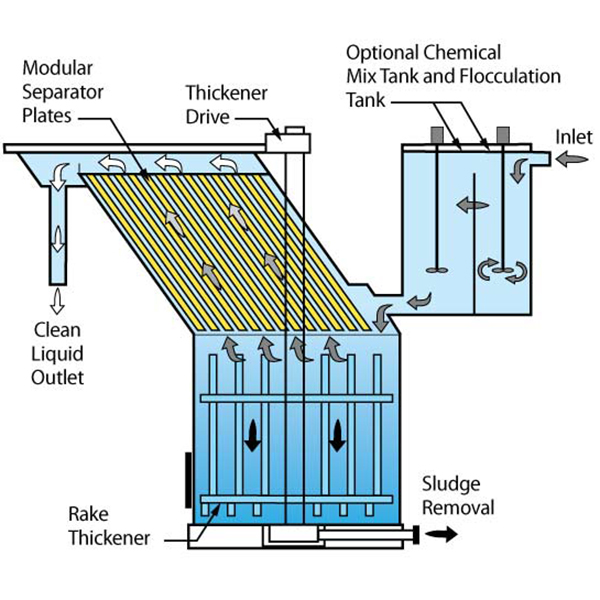

1. Naqshad Fudud: Ma jiraan qaybo dhaqaaqa iyo dayactir yar.

-

2. Qaab-dhismeed Waara: Laga sameeyay bir kaarboon ah oo leh dahaadh epoxy ah ama dahaadh FRP ikhtiyaari ah.

-

3. Raad-raac yar: Waxay u baahan tahay meel yar oo lagu rakibo waxayna yareysaa kharashka kaabayaasha.

-

4. Tamarta Waxtarka Leh: Waxay ku shaqeysaa isticmaalka korontada oo hooseeya.

-

5. Is-dhexgalka Caadiga ahIsku xirka flange-ka caadiga ah si loogu fududeeyo is-dhexgalka.

-

6. Hawlgal joogto ah: Waxay awood u siineysaa daaweyn deggan oo aan kala go 'lahayn.

-

7. Si Fudud Loo Shaqeeyo: Nidaamka isticmaalaha oo si dhakhso leh loo habeyn karo loona dayactiri karo.

Waxyaabaha ugu muhiimsan ee waxqabadka

-

✅Heerka ka saarista birta ion: in ka badan 93%

-

✅Ka saarista Koodhka: ilaa 80% iyadoo ku xiran warshadaha

-

✅Yaraynta ciriirigalaga bilaabo 1600 mg/L ilaa 5 mg/L

-

✅Ka saarista adkaha la hakiyey: in ka badan 95%

-

✅Ka saarista isbeddellada: ilaa 90%

Codsiga

Cadayaha lamella ee Holly wuxuu ku habboon yahay codsiyo badan oo warshadeed iyo kuwo degmo, oo ay ku jiraan:

-

1. Daaweynta biyaha ee degmada

-

2. Biyaha wasakhda ah ee kiimikada iyo birta culus (Cu, Fe, Zn, Ni)

-

3. Biyaha wasakhda ah ee macdan qodista dhuxusha

-

4. Rinjiyeynta dharka iyo daabacaadda biyaha wasakhda ah

-

5. Warshadaha maqaarka, cuntada, iyo cabitaanka

-

6. Biyaha wasakhda ah ee warshadaha kiimikada

-

7. Burcad iyo biyo cad oo warqad ah

-

8. Dib-u-habaynta biyaha dhulka hoostiisa ah

-

9. Shaandhaynta milixda iyo daadinta qashinka lagu shubo

-

10. Daawaynta biyaha roobka iyo qaboojinta ee munaaradda

-

11. Biyaha wasakhda ah ee warshadda baytariga, dahaadhka, iyo kan wax lagu dahaadho ee semiconductor-ka.

-

12. Daaweyn hore oo loogu talagalay nidaamyada biyaha la cabi karo

Baakad

Shaandheeyayaashayada lamella si taxaddar leh ayaa loogu duubaymaraakiib caalami ah oo ammaan ah. Qayb kasta waa la duubay oo sanduuqyo ayaa lagu dhejiyay si looga hortago waxyeello inta lagu jiro safarka. Baakad gaar ah ayaa sidoo kale la heli karaa iyadoo lagu saleynayo baahiyahaaga.

Tilmaamaha

| Moodel | Awoodda | Alaab | Cabbirrada (mm) |

| HLLC-1 | 1m³/saacaddii | Bir Kaarboon (Rinjiyeysan Epoxy) / Bir Kaarboon + Dahaarka FRP | Φ1000 * 2800 |

| HLLC-2 | 2m³/saacaddii | Φ1000 * 2800 | |

| HLLC-3 | 3m³/saacaddii | Φ1500 * 3500 | |

| HLLC-5 | 5m³/saacaddii | Φ1800 * 3500 | |

| HLLC-10 | 10m³/saacaddii | Φ2150 * 3500 | |

| HLLC-20 | 20m³/saacaddii | 2000 * 2000 * 4500 | |

| HLLC-30 | 30m³/saacaddii | 3500*3000*4500 Aagga Fadhiga: 3.0*2.5*4.5m | |

| HLLC-40 | 40m³/saacaddii | 5000*3000*4500 Aagga Fadhiga: 4.0*2.5*4.5m | |

| HLLC-50 | 50m³/saacaddii | 6000*3200*4500 Aagga Fadhiga: 4.0*2.5*4.5m | |

| HLLC-120 | 120m³/saacaddii | 9500*3000*4500 Aagga Fadhiisinta: 8.0*3*3.5 |